TSA Approved Cable Luggage Locks, Re-settable Combination with Alloy Body

$23.75 (as of February 22, 2025 12:34 GMT +00:00 - More info)Immensa, a leading 3D printing firm based in the UAE, has partnered with assurance company DNV to release the world’s first global guideline for digitizing spare parts, marking a transformative step for the energy and power sectors. This initiative comes in response to the increasing disruptions in global supply chains caused by geopolitical conflicts and climate-related issues. By providing a structured process to assess, create digital twins, and 3D print spare parts on-demand, the guideline aims to promote sustainable economic growth, enhance global competitiveness, and support national industrial initiatives in the Gulf region. Expected to address $30 billion in annual losses for energy companies, this groundbreaking guideline not only underscores Immensa’s strategic collaborations but also sets a new standard in supply chain security and efficiency. Have you ever wondered how we can tackle the ever-growing challenges in the supply chain, especially in the critical energy and power sectors? Imagine if there was a way to revolutionize how spare parts are managed, making them easier, cheaper, and faster to source. Well, that’s exactly what UAE-based 3D printing firm Immensa, in collaboration with the assurance company DNV, has aimed to achieve. They’ve recently released the world’s first global guideline for digitizing spare parts, and it’s a game-changer. Let’s dive into what this means for you and the industry.

Search vacation packages & trips

The Context: Why This Matters Now

Global supply chains are increasingly under strain from numerous factors—geopolitical conflicts, climate-related disruptions, and more. These challenges have made it difficult for companies, especially in the energy and power sectors, to maintain a steady supply of crucial spare parts. Interestingly, these sectors spend over $90 billion on spare parts annually. That’s a staggering amount and underscores the importance of having a reliable and resilient supply chain. Immensa and DNV’s new guidelines aim to address these issues head-on.

Goals of the New Guidelines

It’s not just about solving immediate problems. The overarching goals are far-reaching and multifaceted:

- Promote Sustainable Economic Growth: By reducing dependency on traditional supply chains, these guidelines could significantly lower costs and environmental impact.

- Enhance Global Competitiveness: Faster, on-demand production of spare parts allows companies to be more agile and responsive.

- Support National Industrial Initiatives in the Gulf Region: This offers a way to boost local manufacturing capabilities, thus enhancing regional competitiveness.

These goals aren’t just ambitions; they’re practical steps towards a more resilient and efficient future.

CEO Statement: A Game Changer

According to Immensa’s CEO, Fahmi Al Shawwa, this new guideline is a real “game changer” for supply chain security. Given the frequent disruptions, a more secure, reliable, and swift way of sourcing spare parts is invaluable. Imagine not having to wait weeks or even months for a crucial spare part to arrive. Through digitization and 3D printing, what you need can be produced on-demand, right where it’s required.

What the Guidelines Entail

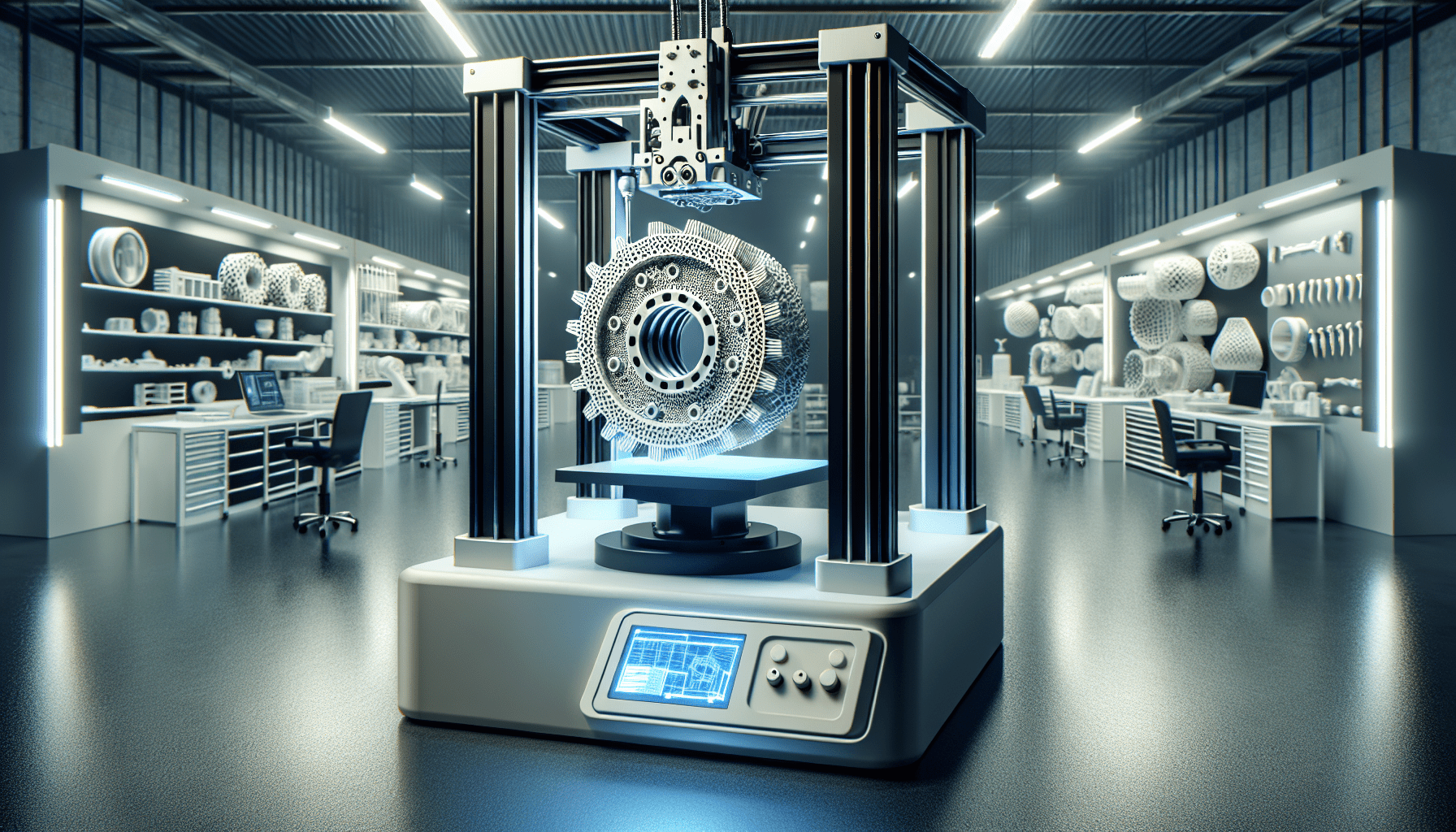

So, what exactly do these guidelines cover? They outline a comprehensive process for digitizing and 3D printing spare parts on-demand. Here’s how it works:

- Assessing the Parts: Identify the spare parts that are suitable for digitization and 3D printing.

- Creating Digital Twins: Develop a digital model of the spare part, often referred to as a digital twin.

- Using 3D Printing: Produce the spare parts using advanced 3D printing technology.

By following these steps, companies can transition from traditional supply chains to a more dynamic and flexible system.

Top domestic vacation destinations

Development of the Guidelines

Developing these guidelines was no small feat. A team of 10 experts from Immensa and DNV spent over five months crafting them. They didn’t do this in isolation; instead, they leveraged insights from customers to ensure that the guidelines are practical and meet real-world needs.

Here’s a quick snapshot of the development process:

| Phase | Activities | Duration |

|---|---|---|

| Planning | Initial framework and consultation | 1 Month |

| Research | Gathering customer insights and technical specifications | 2 Months |

| Drafting | Writing and refining guidelines | 1.5 Months |

| Review | Internal and external review | 0.5 Month |

| Finalizing | Final adjustments and publication | 0.5 Month |

Financial Impact

The potential financial impact of these guidelines is enormous. Currently, energy companies face annual losses of about $30 billion due to supply chain disruptions. By enabling quick and efficient digitization and 3D printing of spare parts, these guidelines could significantly mitigate these losses. Additionally, they offer quick assessment capabilities using AI, helping firms make faster and more accurate decisions.

DNV: Established Expertise

DNV is not new to setting high standards. Established in 1864, this company has been a leader in technical standards, particularly in offshore pipeline design. Their experience and expertise bring a level of credibility and reliability to the guidelines, ensuring they are robust and effective.

Strategic Partnerships

Immensa isn’t stopping here. They’re expanding their reach through strategic partnerships, notably with Pelagus 3D for maritime and offshore applications. These collaborations help extend the applicability and adoption of the guidelines across different sectors, enhancing their overall impact.

The Industry Trend: Digital Inventories and 3D Printing

The move towards digitizing inventories and using 3D printing is not just a trend; it’s becoming a necessity. Companies like Würth Additive Group and 3YOURMIND are embracing this shift, using digital inventories and 3D printing to improve their supply chain management.

Benefits of Digital Inventories

Let’s break down some of the key benefits of having digital inventories:

- Reduced Downtime: With on-demand 3D printing, parts are produced as needed, drastically reducing downtime.

- Cost Efficiency: Reduces the need for large physical inventories, saving storage costs.

- Flexibility: Easier to adapt to changes in demand or design.

Case Study: Würth Additive Group

Würth Additive Group is a great example of this trend in action. They have implemented digital inventories to manage their spare parts more efficiently. The result? Significant cost savings and improved operational efficiency.

Adoption Challenges

Of course, adopting digital inventories and 3D printing isn’t without its challenges:

- Initial Investment: The upfront costs for setting up 3D printing capabilities can be high.

- Technical Expertise: It requires specialized knowledge to properly digitize and print parts.

- Quality Assurance: Ensuring the printed parts meet quality standards is crucial.

However, the long-term benefits often outweigh these initial challenges, making it a smart investment for many companies.

Looking Forward: The Future of Spare Parts Management

By now, you can see how transformative these new guidelines could be. But what does the future hold? Here are some predictions:

Broader Adoption

As more companies see the benefits, it’s likely that adopting digital inventories and 3D printing will become standard practice across various industries.

Technological Advancements

Expect further advancements in 3D printing technology, making it even more efficient, cost-effective, and versatile.

Policy and Standards

With DNV’s involvement, it’s probable that similar standards and guidelines will be developed, further driving the adoption of these practices.

Environmental Impact

By reducing waste and dependency on long supply chains, these guidelines can contribute to more sustainable practices, a crucial aspect in today’s world.

Conclusion

The release of these new guidelines by Immensa and DNV marks a significant milestone in the realm of spare parts management. With the potential to save billions of dollars, enhance supply chain security, and support sustainable economic growth, these guidelines are indeed a game-changer. Whether you’re in the energy sector or any other field that relies heavily on spare parts, adopting these practices could offer tremendous benefits.

Isn’t it exciting to think about how far we’ve come and where we’re headed? The future of spare parts is digital, and it’s time we embrace it.