Mrsdry Travel Bottles for Toiletries, Tsa Approved 3oz Travel Size Containers BPA Free Leak Proof Refillable Liquid Silicone Squeezable Travel Accessories for Shampoo Conditioner Lotion (4 Pack)

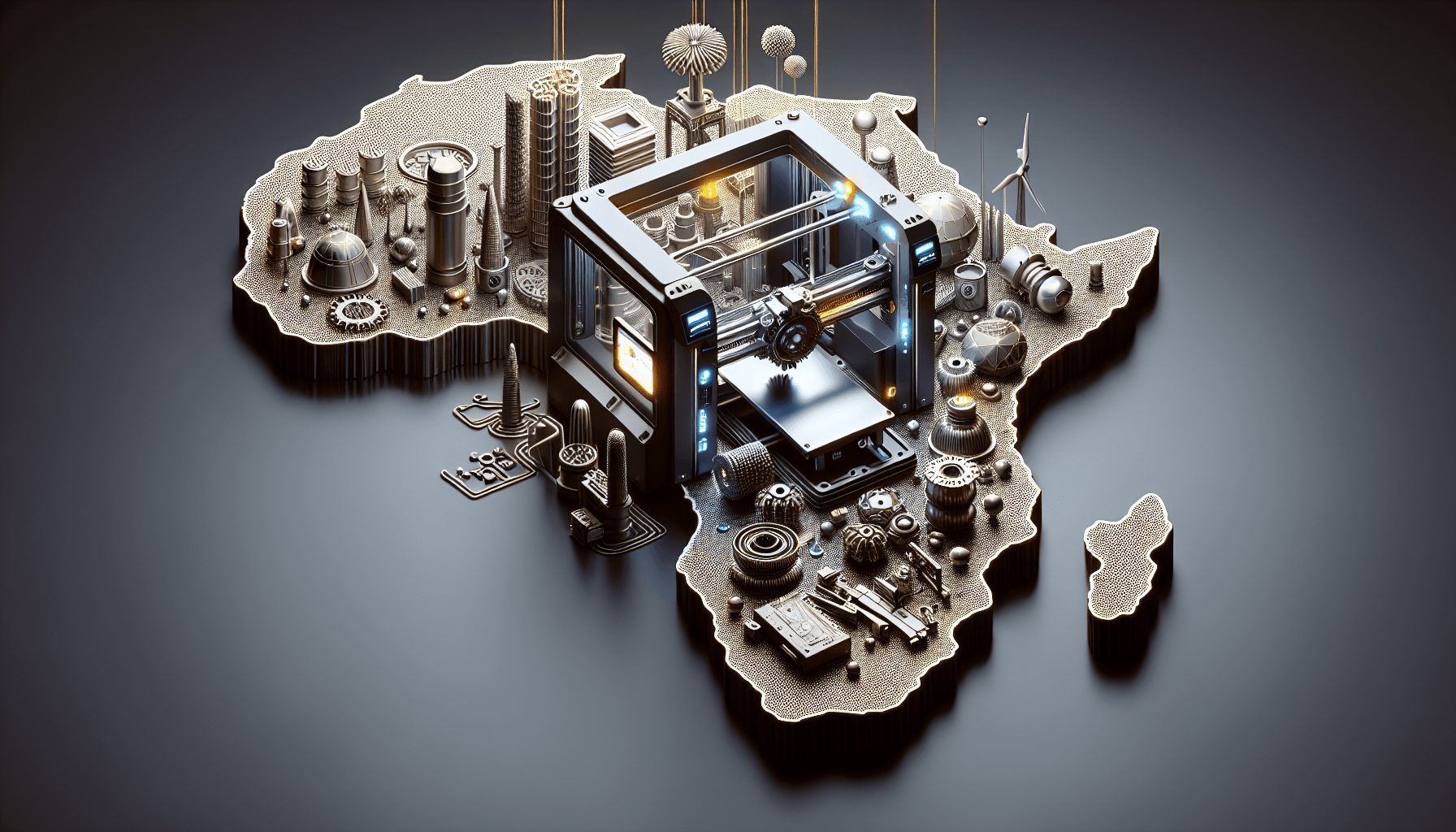

$9.99 (as of December 24, 2024 22:01 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)SPEE3D and RusselSmith have announced an exciting strategic partnership to introduce cold spray 3D printing technology to West Africa, with a primary focus on Nigeria’s oil and gas, defense, and commercial industries. Through this collaboration, RusselSmith will become a regional partner and reseller for SPEE3D’s advanced metal 3D printers, including the innovative WarpSPEE3D. This groundbreaking technology addresses key challenges such as maintaining equipment and procuring legacy parts, promising to create more secure local supply chains and reduce operational delays and costs. With this partnership, RusselSmith is set to become Africa’s leader in advanced additive manufacturing solutions, providing faster and scalable production capabilities which significantly improve uptime and sustainability for various sectors. Have you ever wondered how the latest advancements in 3D printing could revolutionize industries in West Africa? Well, you’re in for an exciting read because SPEE3D and RusselSmith have recently announced a groundbreaking partnership set to do just that. Let’s dive into the details of this strategic collaboration and explore how it’s poised to transform sectors like oil and gas, defense, and commercial industries in Nigeria.

SPEE3D and RusselSmith Announce Strategic Partnership for West Africa

This partnership between two innovative companies aims to bring cutting-edge technology to West Africa, addressing critical challenges and opening up new opportunities.

Search vacation packages & trips

Partnership Announcement

SPEE3D, a pioneer in cold spray 3D printing, has teamed up with RusselSmith to introduce their advanced metal 3D printing solutions across West Africa. RusselSmith, already an established player in the Nigerian oil and gas sector, will serve as a regional partner and reseller of SPEE3D’s metal 3D printers. This collaboration is expected to cater primarily to the oil and gas, defense, and commercial sectors in Nigeria, bringing advanced manufacturing capabilities to the region.

- Key Highlights:

- SPEE3D: Known for its cold spray 3D technology.

- RusselSmith: Regional partner and reseller.

- Target Industries: Oil and gas, defense, commercial.

Benefits & Objectives

The partnership aims to address several pain points within these industries, providing a myriad of benefits and clearly defined objectives.

-

Secure Local Supply Chains: One of the primary goals is to create secure local supply chains, enabling industries to source materials and parts locally rather than relying on imports.

-

Maintenance and Legacy Parts: The technology will help in maintaining critical equipment and procuring legacy parts that are otherwise difficult to source.

-

Cost and Time Efficiency: By reducing operational delays and cutting costs, 3D printing will offer a faster and more economical way to produce essential parts.

-

Table of Key Benefits:

| Benefit | Description |

|---|---|

| Secure Local Supply Chains | Reduces dependency on international suppliers, increasing reliability and speed. |

| Maintenance | Easily produce parts for equipment maintenance, ensuring minimal downtime. |

| Legacy Parts | Manufacture obsolete or hard-to-find parts on-demand. |

| Cost Efficiency | Lower production costs through localized manufacturing. |

| Time Efficiency | Accelerated production schedules reduce operational delays. |

Technology & Equipment

Central to this partnership is the acquisition of advanced technology that makes all these benefits possible.

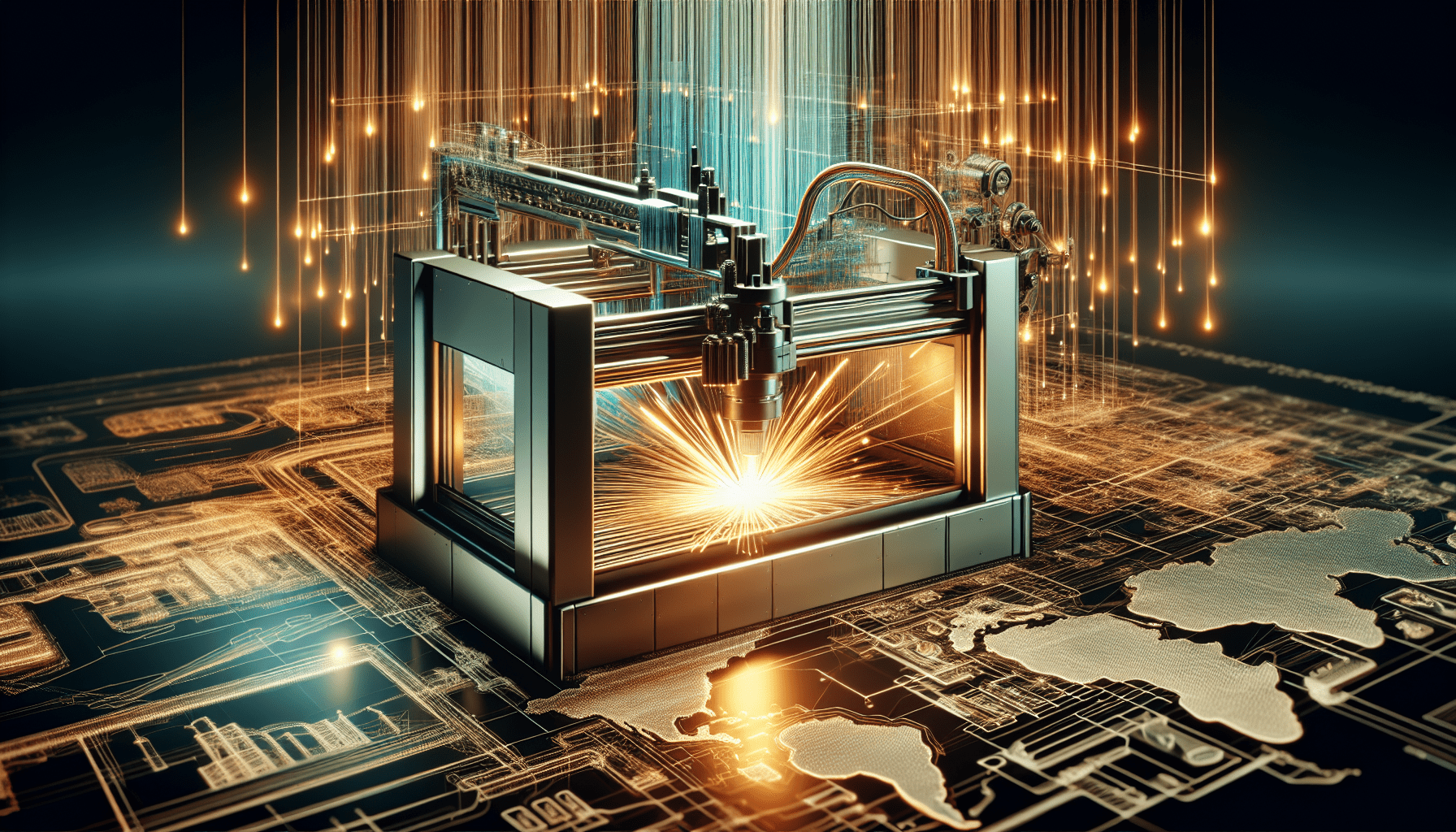

WarpSPEE3D 3D Printer

RusselSmith has invested in the WarpSPEE3D 3D printer, which uses cold spray technology to manufacture metal parts efficiently. Unlike traditional 3D printing methods, cold spray technology fires metal powder particles at supersonic speeds to form solid structures upon impact. This not only leads to faster production times but also makes the process highly scalable, suitable for various industrial applications.

-

Key Features:

- Fast Production: Capable of producing metal parts at unprecedented speeds.

- Scalability: Can easily scale up for larger production runs.

- On-Demand Manufacturing: Enables production whenever parts are needed, streamlining supply chains.

-

How It Works:

- Metal Powder Preparation: The process begins with preparing the specific metal powder required for the part.

- Supersonic Spraying: The powder is then accelerated to supersonic speeds using compressed air or gas and directed at a substrate.

- Solid Structure Formation: Upon impact, the metal particles bond to form a solid, dense part, layer by layer.

Industry Impact

Both SPEE3D and RusselSmith anticipate a significant impact on various industries in Nigeria and beyond.

A Game Changer

This partnership is seen as a transformative step, potentially positioning RusselSmith as Africa’s leading provider of advanced additive manufacturing solutions. The implementation of SPEE3D technology is expected to set new benchmarks for uptime and sustainability, directly benefiting customers by enhancing the reliability and efficiency of their operations.

- Customer Benefits:

- Improved Uptime: Enhanced equipment availability and reliability.

- Sustainable Solutions: Environmentally friendly manufacturing processes.

- Reduced Lead Times: Faster turnaround for critical parts.

RusselSmith’s History with 3D Printing

RusselSmith is no stranger to 3D printing technology. Their prior investments and applications in this field reveal a deep commitment to leveraging advanced manufacturing techniques.

Previous Investments

RusselSmith has already invested heavily in 3D printing, particularly for the Nigerian oil and gas sector. One of their notable acquisitions includes ROBOZE 3D printers, which are known for producing functional and corrosion-resistant parts. These investments have placed RusselSmith at the forefront of innovating within the industry.

-

Noteworthy Milestones:

- ROBOZE 3D Printers: Enabled production of durable and corrosion-resistant components.

- Industry Leadership: First African company inducted into the Additive Manufacturing Green Trade Association.

-

Their 3D Printing Journey:

- Adoption of ROBOZE: Focused on producing functional parts that can withstand harsh conditions.

- Recognition: Earned industry accolades for their forward-thinking approach and commitment to sustainable manufacturing practices.

Global Context & Adoption

RusselSmith and SPEE3D are not alone in recognizing the potential of 3D printing within the energy sector.

International Adoption

Globally, there’s a growing trend of adopting additive manufacturing technologies, particularly in the energy sector. Companies like NAMI in Saudi Arabia and Westinghouse Electric in the USA are leveraging these technologies to address critical industry challenges.

-

Examples of Global Adoption:

- NAMI (Saudi Arabia): Utilizes 3D printing for repair and maintenance of energy sector equipment.

- Westinghouse Electric (USA): Employs additive manufacturing to produce essential parts, improving efficiency and creating secure supply chains.

-

Why It Matters:

- Efficiency: Accelerates the production of critical components, reducing downtime.

- Supply Chain Security: Enhances local sourcing to mitigate supply chain disruptions.

- Cost Savings: Reduces expenditure on importing parts and delays caused by international shipping.

Conclusion

This comprehensive overview of the SPEE3D and RusselSmith partnership highlights the huge potential and far-reaching implications of bringing cold spray 3D printing technology to West Africa. From securing local supply chains and reducing costs to improving equipment uptime and sustainability, the anticipated benefits are vast and varied.

Would you like to stay updated on how this partnership evolves and impacts industries in West Africa? Keep an eye out for more developments in this space, as this collaboration promises to shape the future of manufacturing in the region.

Top domestic vacation destinations